Garage Door Insulation for Comfort and Efficiency

Before building out our custom woodshop, one of the first and most important steps we took was insulating the garage doors. Temperature swings can make working in the garage unbearable in both summer and winter—and insulation was key to creating a more comfortable, energy-efficient space year-round.

Why We Insulated the Doors

Metal garage doors are notorious for letting heat in during the summer and leaking warmth in the winter. Since we planned to spend long hours woodworking, assembling projects, and using sensitive materials, regulating the interior climate became a top priority.

Our Process

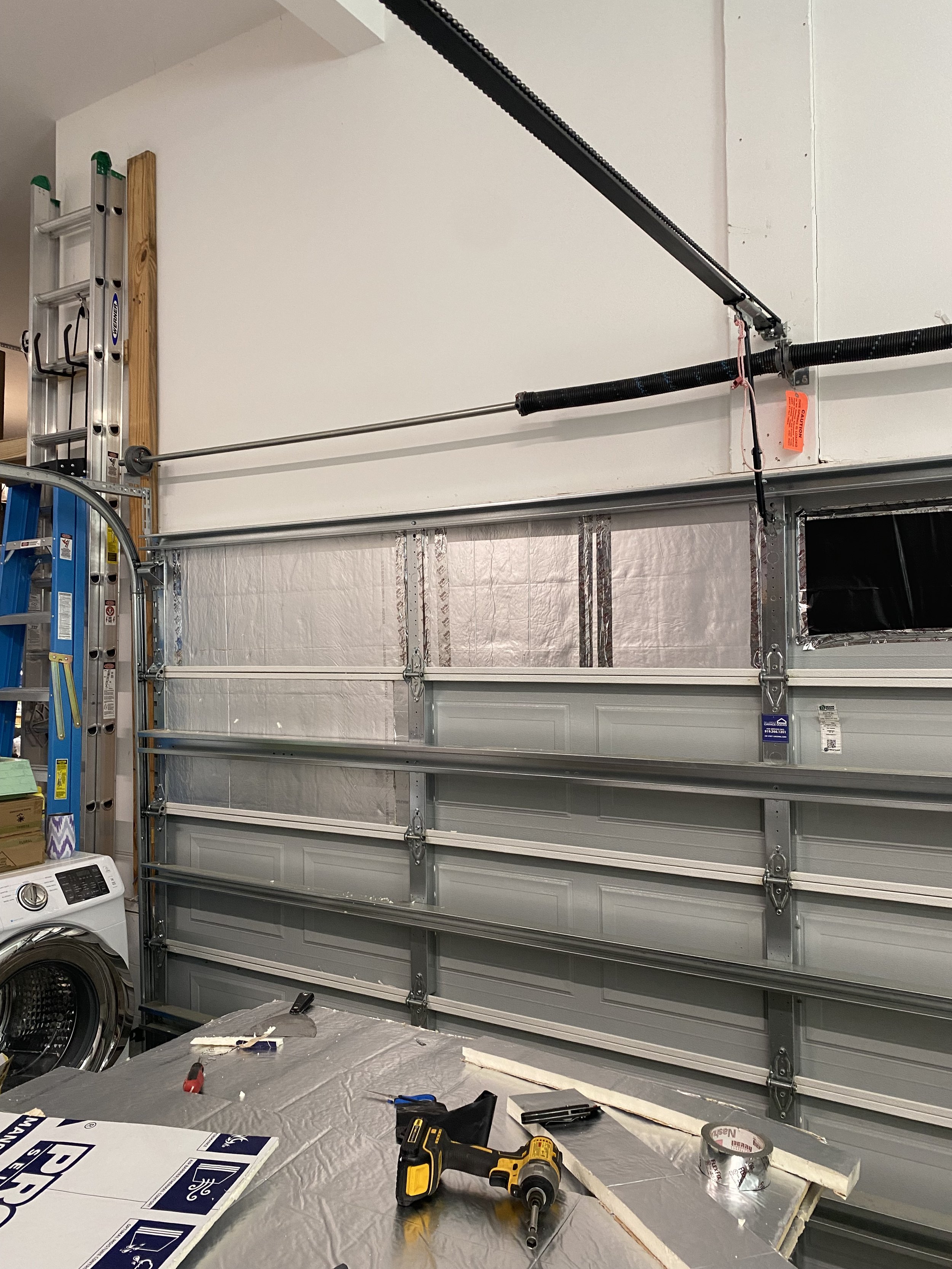

We used rigid foam board insulation panels with a foil-faced reflective surface to improve both R-value and radiant heat protection.

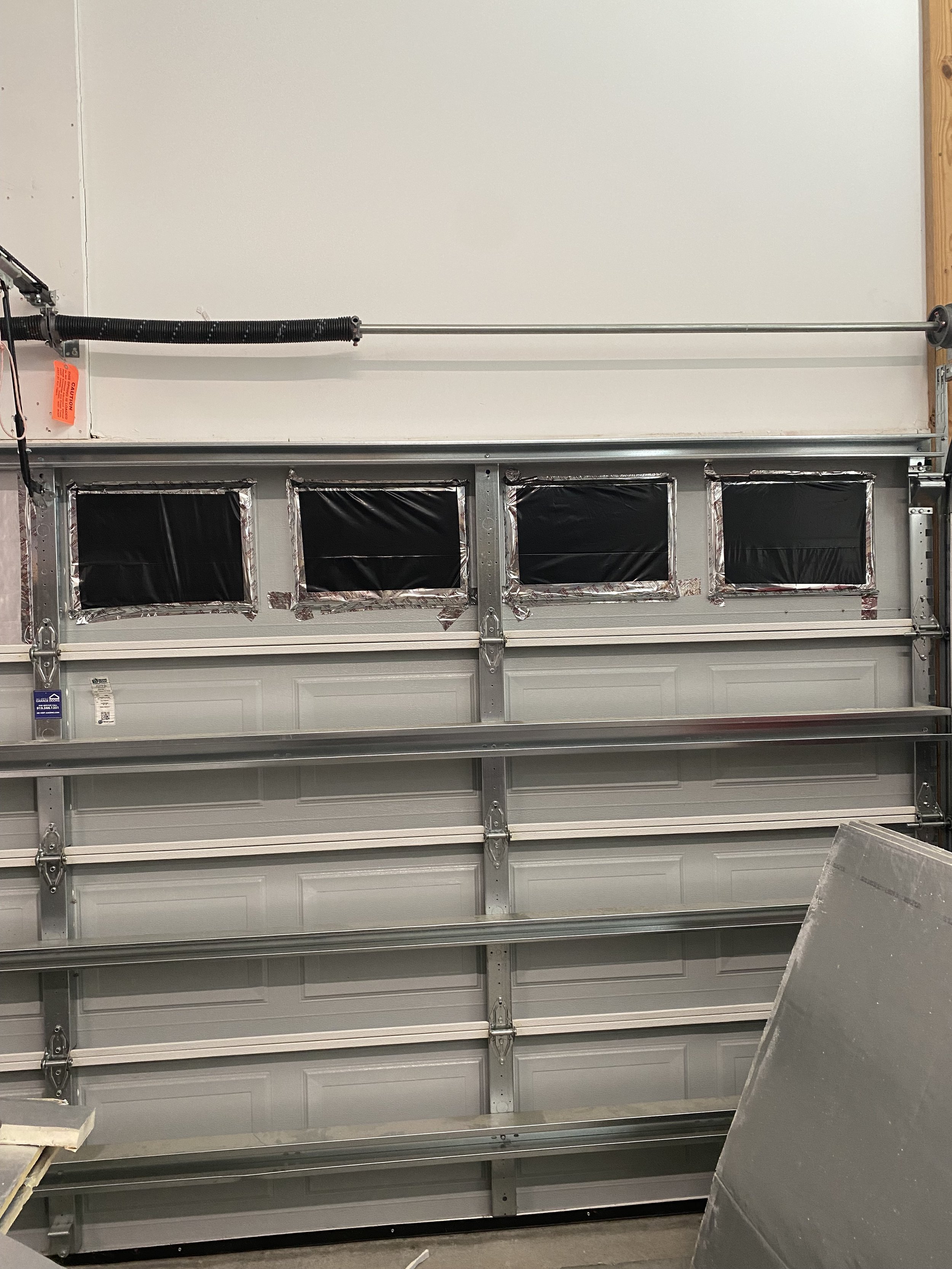

Each panel was custom-measured and cut to fit snugly inside the garage door channels for a secure, flush finish.

Foil tape and adhesive backing ensured the panels remained in place over time, even with repeated door use.

For the top windows, we added blackout inserts with a sealed barrier to prevent heat gain while maintaining a clean look from outside.

Care was taken to avoid obstructing the garage door’s mechanical operation, springs, or safety features.

The Results

The difference was immediate. With the doors insulated, the garage retained heat in the winter and stayed significantly cooler in the summer. This made it a far more usable space for our woodworking shop, especially when paired with additional insulation and airflow improvements inside the garage.

This garage door insulation step laid the foundation—literally and figuratively—for what became a highly functional and enjoyable home workshop. Every project starts with good prep, and this one made all the difference.